CES presentation: what was announced

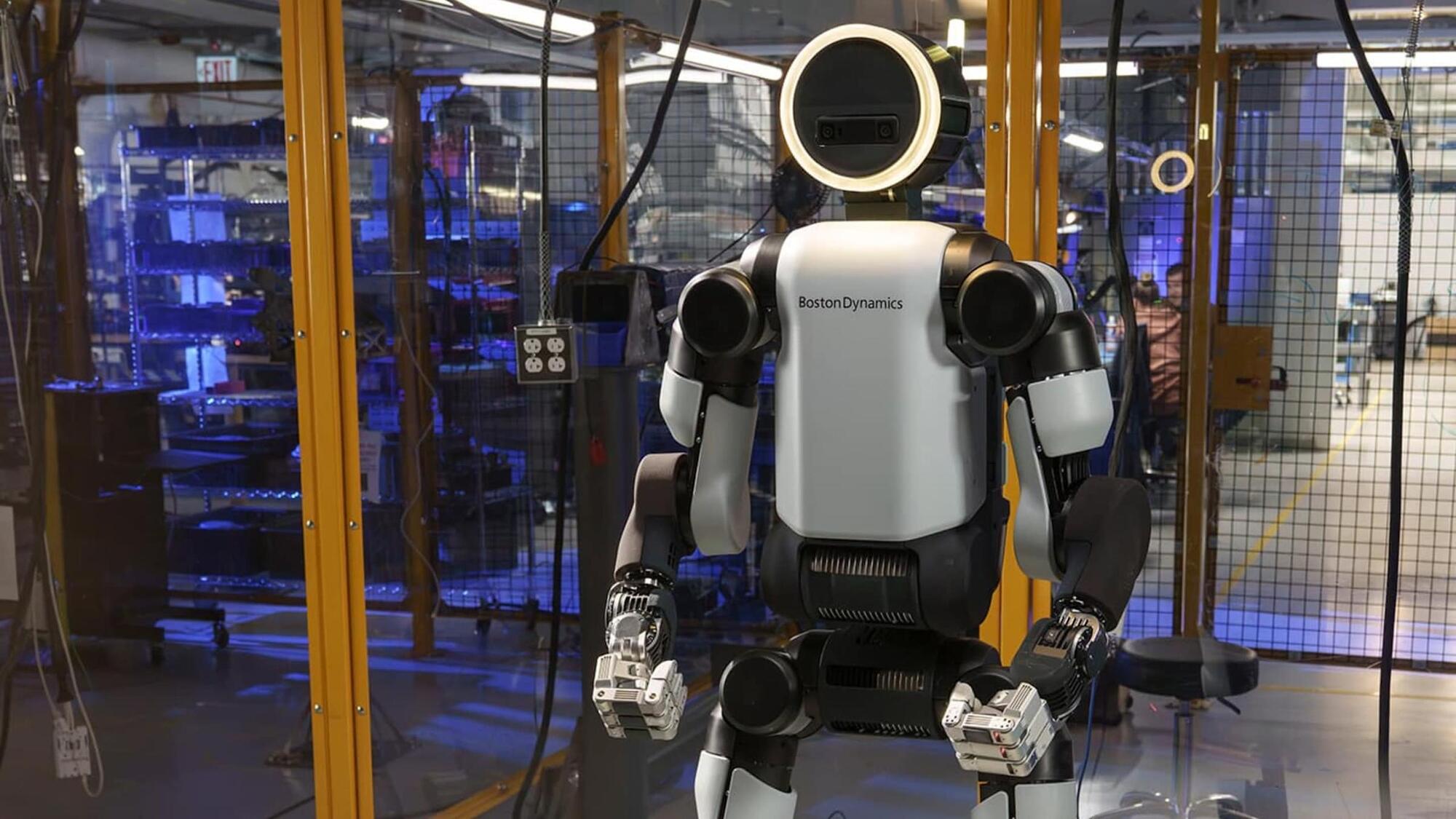

At CES 2026 Boston Dynamics confirmed that the final version of the humanoid robot Atlas is ready for mass production. The first partners to receive the robot are the corporation Hyundai (a shareholder) and Google DeepMind — the team that will test artificial intelligence models for robotics.

"The final version of Atlas is ready for deployment"

— Boston Dynamics, CES 2026 press release

Technical facts in a few figures

Atlas is positioned as an industrial robot with three operating modes: autonomous, operator-controlled and via tablet. Key specifications: payload up to 50 kg, reach of approximately 2.3 m, operating temperature range from -20°C to +40°C. These figures make Atlas suitable for complex manufacturing operations and logistics in both moderate and extreme conditions.

Partners and practical scenarios

Hyundai plans to begin using Atlas at its plants from 2028 for work with auto parts, and from 2030 — for assembling components and routine complex operations. Google DeepMind will receive Atlas to test Gemini Robotics models with the aim of teaching robots to make more complex autonomous decisions.

This combination of a manufacturing platform and powerful AI is a typical path from research demonstrations to commercial solutions. Social confirmation of market maturity is visible in related cases: the robot dog Spot is already used by police in the US and Canada, and in China columns of robots were shown in mass demonstrations — a signal that robotic systems are entering wider use.

Why this matters for Ukraine

Boston Dynamics' technological progress is not only about engineering — it’s about changing the rules in industry, defense and reconstruction. For Ukraine the key consequences are: higher demands on local mechatronics and AI, opportunities to deploy robots in rebuilt production lines and logistics, and risks associated with autonomous systems in the security sector.

Practically, this means Ukrainian enterprises and state institutions must monitor integration standards, invest in workforce training and create legal frameworks for the safe use of robots during infrastructure reconstruction and in supply chains.

What’s next

The launch of a serial Atlas is a signal that the gap between laboratory demonstrations and industrial application is shrinking. For Ukraine this is simultaneously an opportunity and a challenge: an opportunity to attract investment in automation and training, and a challenge to adapt regulation and security systems in time.

It is now important that partnership announcements turn into contracts and knowledge exchange — and that Ukraine uses these technologies not only for business efficiency, but also to strengthen the resilience of critical infrastructure.